OIL EXTRACTION

Mechanical Extraction

Oil extraction by mechanical expellers or presses is the most conventional method. In this method, either a manual ram press or an engine-driven screw press is used for the extraction of oil. It has been observed that the ram press can extract around 60%–65% of oil while an engine-driven screw press can extract around 68%–80% of the available oil from seeds.

The design of the mechanical press is very important as it plays a crucial role in the yield of oil. The yield can be increased by the pre-treatment of the seeds by a cooking process to around 89% in single pass and 91% in a dual pass. Oil extracted from a mechanical press needs further treatment by filtering and degumming.

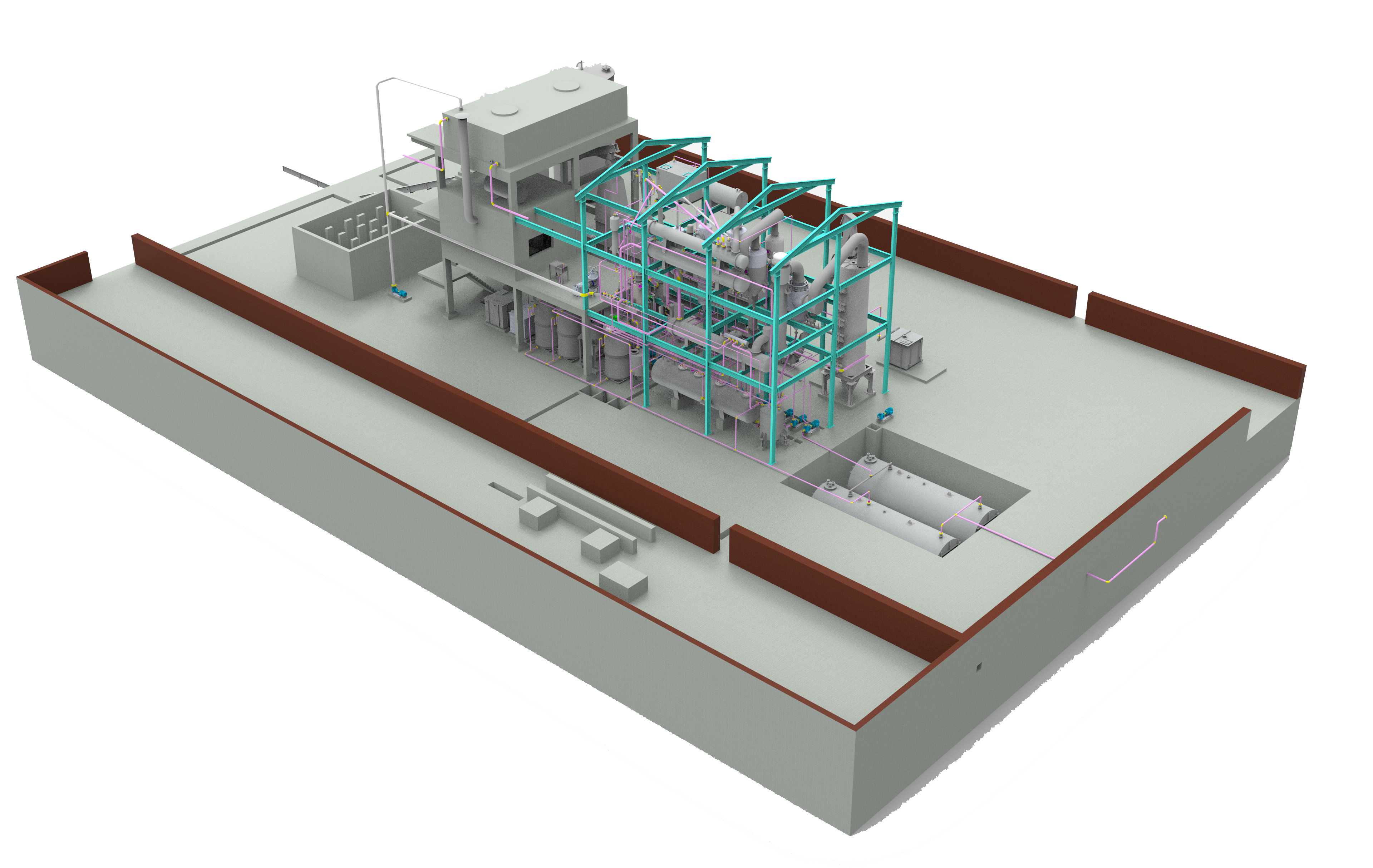

Oil Extraction

Solvent Extraction is the most efficient method of oil recovery from oil bearing materials. It is particularly advantageous for processing of those oilseeds/oil bearing materials which have low oil content viz, soybean, rice bran, mango kernels etc. The flakes of other oilseeds, e. g. groundnut, rapeseed/mustard, sunflower, linseed, etc. disintegrate in contact of solvent and create problems due to production of fine products. This problem is overcome by using pro-pressed cakes of these oilseeds for solvent extraction.

Pro-pressing in expellers also recovers a major portion of oil from these seeds. However, pre-pressed cakes containing 12-20% oil require flaking prior to their solvent extraction for efficient recovery of oil. Solvent extraction plants are either batch or continuous types. However, the continuous counter current percolation systems are more popular in use because of its better efficiency.