SEED PROCESSING

FX-PCAC: Air Cascade Pre-Cleaner

This machine is a combination of density separator and basket beater separator for better Read More

SEED PROCESSING

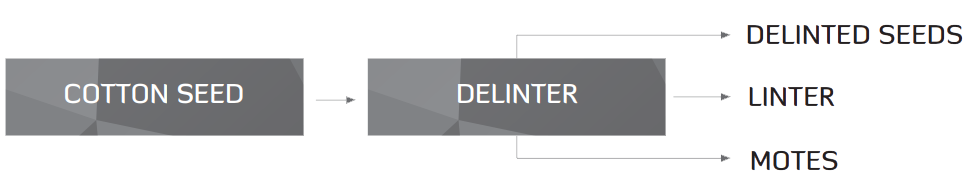

DELINTING OPERATION :