Cotton Seed Processing, Oil Extraction & Refining

Cottonseed can be processed using either the traditional crude method or a scientific approach. The traditional method involves crushing the seed in its un-decorticated form without removing linters, while the scientific process includes delinting, decortication, hull separation, expelling, solvent extraction, and oil refining. The scientific method extracts nearly all the cottonseed oil, whereas the traditional process leaves about 7% residual oil in the oil cake. Despite this residual oil being unnecessary for animal nutrition, it remains in high demand due to misconceptions among dairymen. In contrast, the cottonseed meal obtained through scientific processing contains minimal oil but is rich in by-pass protein (40-42%), which is essential for cattle, as they require more protein rather than oil in their diet.

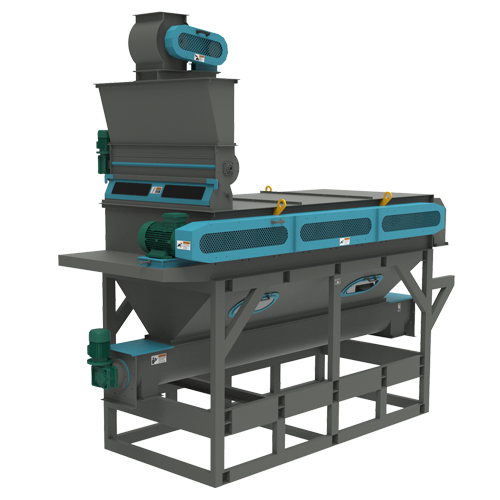

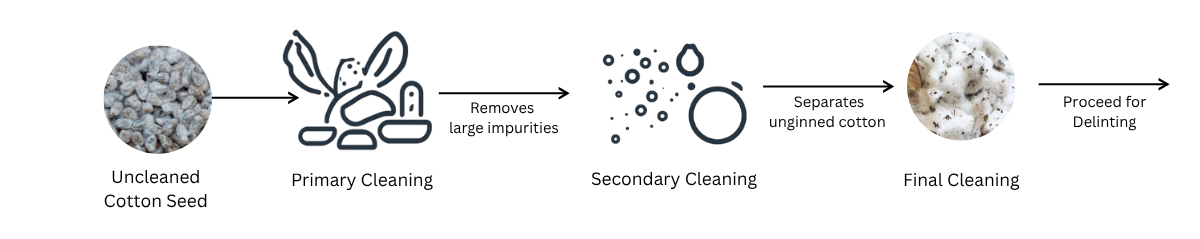

Cleaning Process

The cleaning process ensures seeds are free from impurities before further processing. It follows a three-stage system:

- Primary Cleaning – Removes large impurities like stones, sticks, and oversized debris.

- Secondary Cleaning – Eliminates dust, sand, and fine particles using screens and aspiration.

- Final Cleaning – Separates unginned cotton to ensure clean, uniform seed for better oil recovery.

This process not only protects machinery but also improves seed quality and enhances overall efficiency in oil extraction.

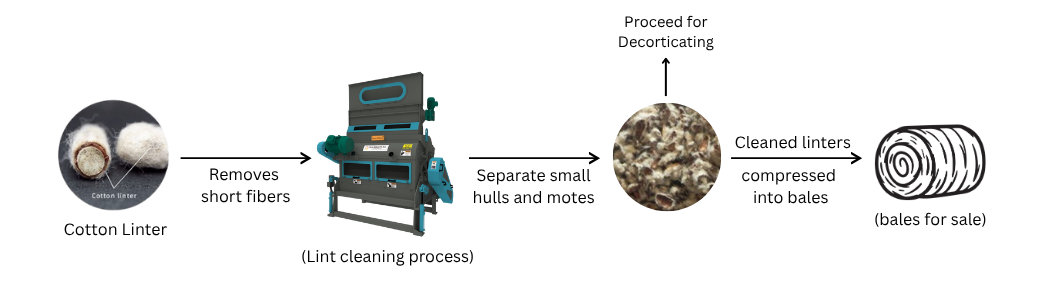

Delinting Process

- Removes short fibers (linters) present on the seed surface.

- Linters are further cleaned through a lint cleaning process to separate small hulls and motes

- Cleaned linters are compressed into bales for sale.

Related Products :

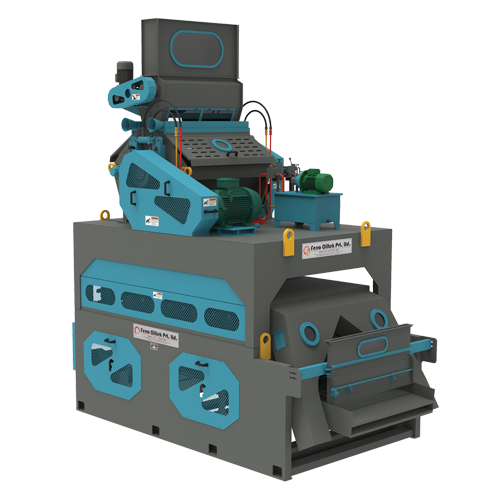

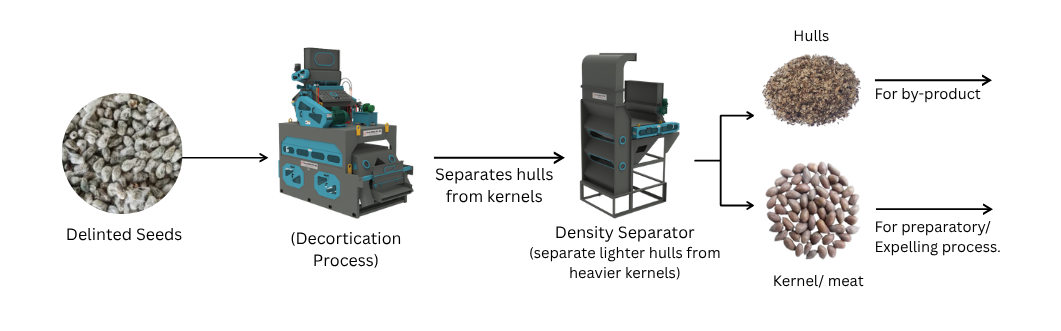

Decortication Process

The delinted cottonseed is processed through the decortication system, which ensures efficient separation of hulls and kernels. The process involves:

- Twin roll decorticator with hulls separation basket beater - Breaks the seed and separates hulls from kernels.

- Density Separator - Uses weight difference to separate lighter hulls from heavier kernels.

- Hulls Purifier - Cleans the separated material to achieve up to 99% separation efficiency.

Here we separate the hulls and kernel 99% efficiently. Further by-product hulls are used for boiler fuel or making hulls bale easy for handling reason by using FX-Hulls bale press machine. And kernel/ meat further process to send into preparatory/ Expelling process.

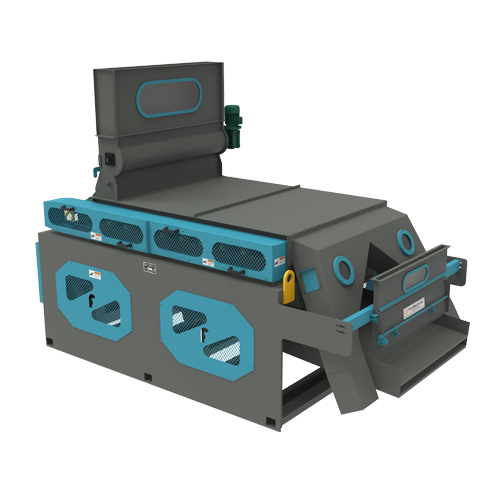

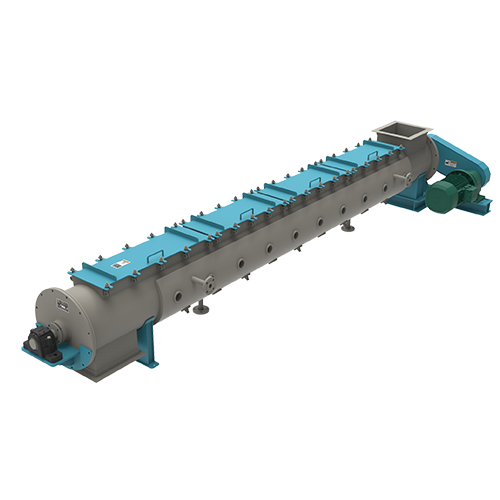

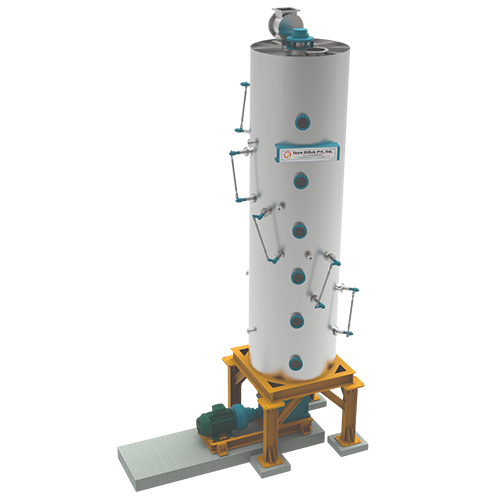

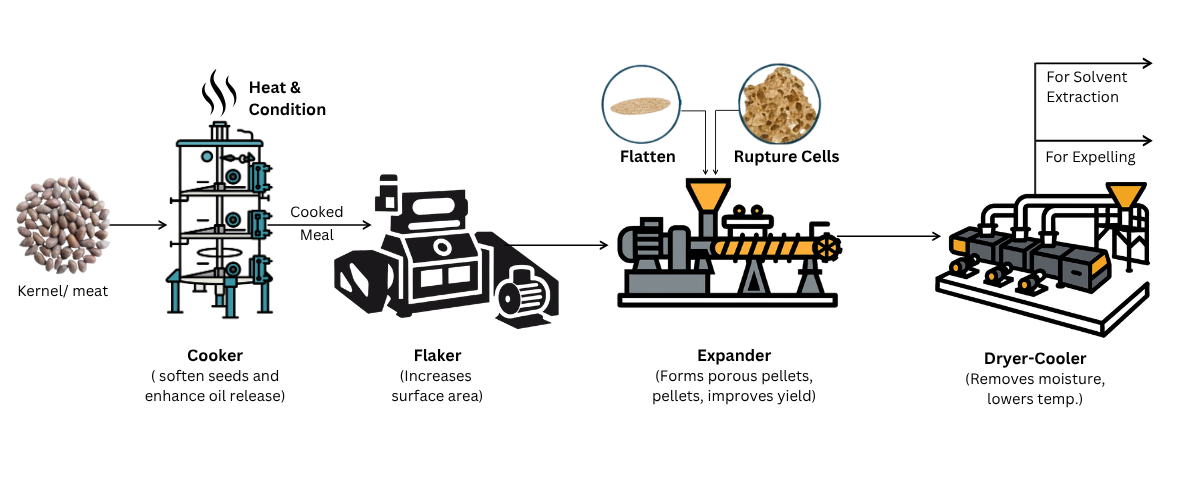

Preparatory

In the edible oil seed preparatory stage, seeds are conditioned to achieve the right texture, moisture, and temperature for maximum oil recovery. This step is crucial as proper preparation directly impacts extraction efficiency, oil yield, and product quality. Key equipment includes:

- Cookers – Heat and condition the seeds, adjusting moisture and temperature to soften the material and enhance oil release.

- Flakers – Flatten the seeds into thin flakes, increasing surface area for efficient solvent penetration during extraction.

- Expanders – Improve oil yield by rupturing seed cells, forming porous expanded pellets that allow better solvent contact and reduce residual oil.

- Dryer-Coolers – Stabilize the expanded material by removing excess moisture and lowering temperature, ensuring consistent quality and safe storage before extraction.

Together, these machines ensure that the seed is perfectly prepared, resulting in higher oil recovery, reduced solvent consumption, and better oil quality.

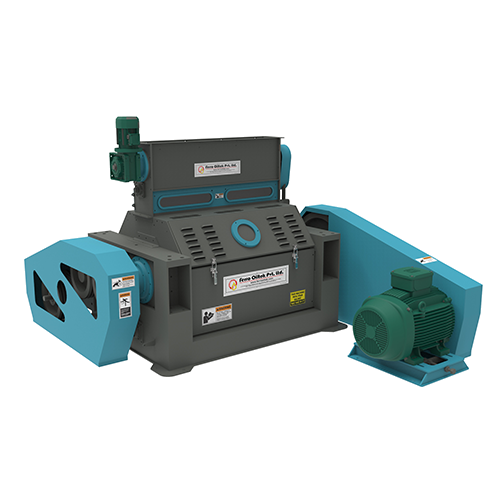

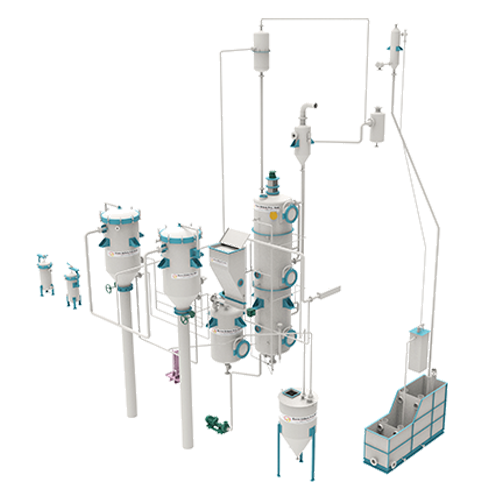

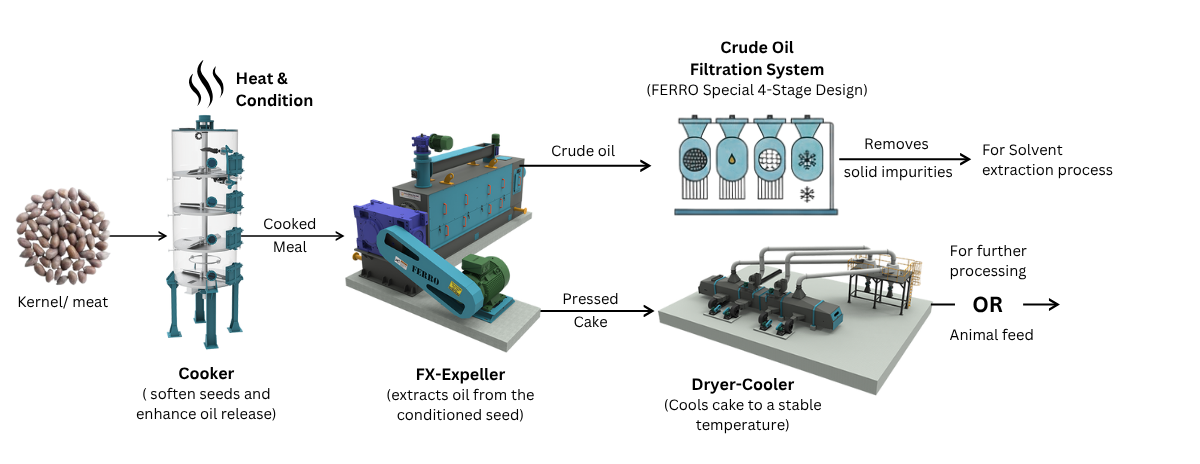

Expelling Process

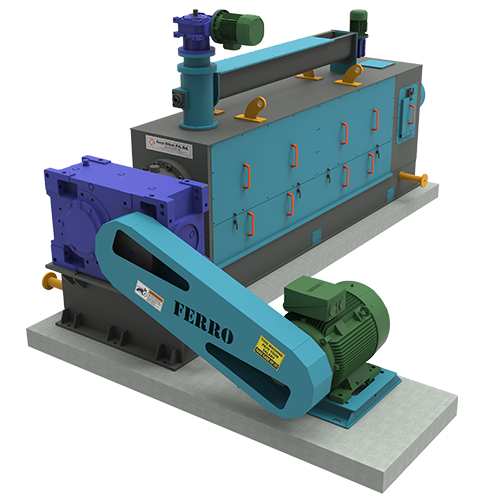

In the cotton seed expelling process, specialized equipment ensures efficient oil recovery and consistent product quality. The key machines include:

- FX-Cooker / FX-Conditioner – Prepares and conditions the cottonseed for expelling by optimizing moisture and temperature, enabling better oil release.

- FX-Expeller – Mechanically extracts oil from the conditioned seed with high efficiency, producing crude oil and pressed cake.

- Crude Oil Filtration System (FERRO Special 4-Stage Design) –Removes solid impurities from the crude oil, ensuring cleaner output and improved quality for refining.

- FX-Cake Cooler – Cools the expelled cake to a stable temperature, preserving its nutritional value and making it suitable for further processing or use as animal feed.

To maximize efficiency, the residual oil in the cake is further recovered through the solvent extraction process, ensuring minimal wastage and maximum yield.

Related Products :

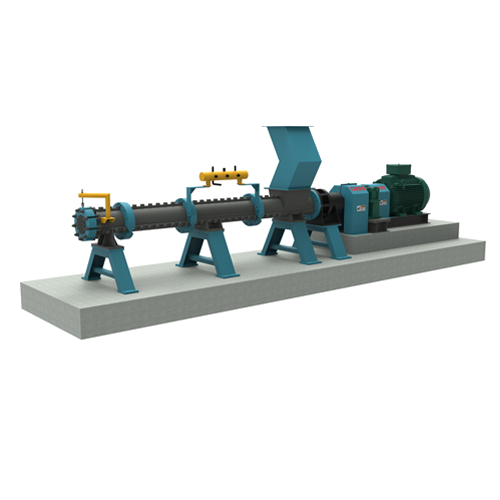

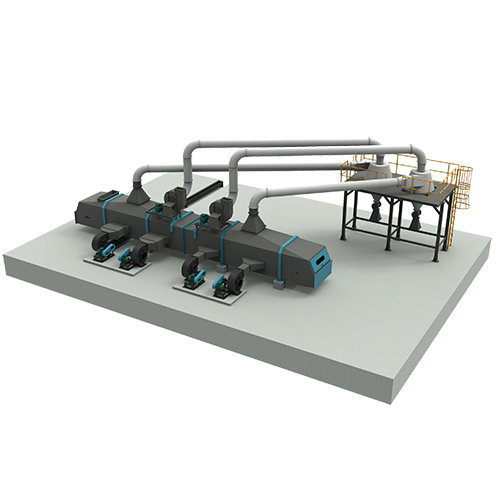

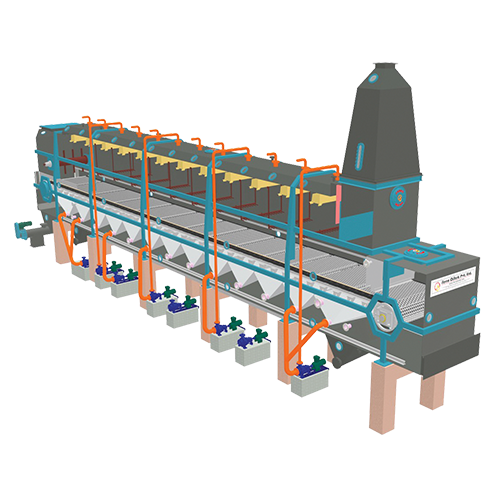

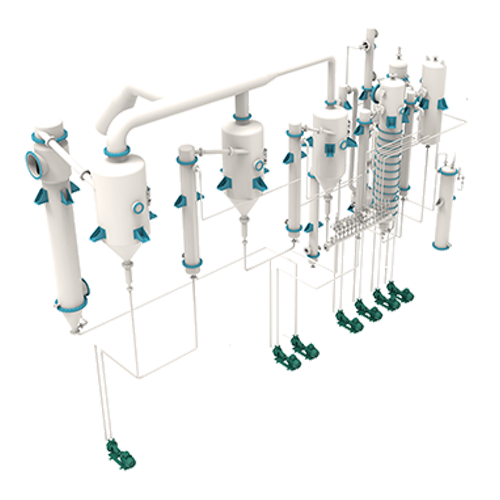

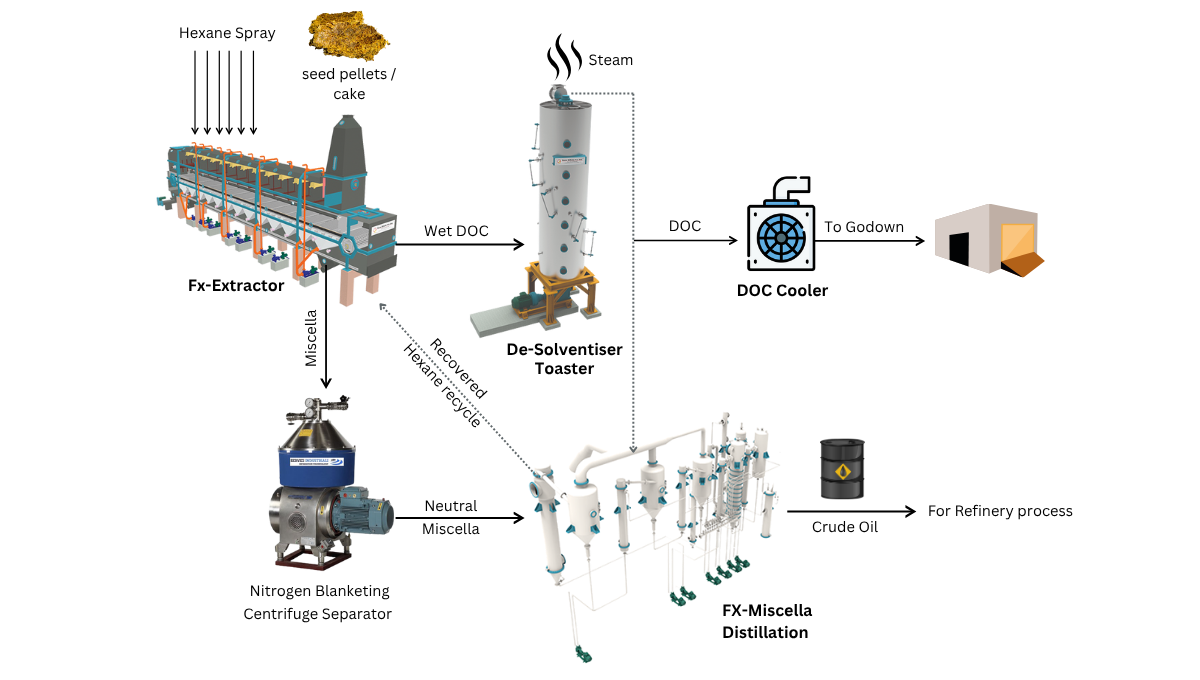

Solvent Extraction

The solvent extraction is a method used to extract oil from oilseeds after preparatory/ mechanical pressing. It involves FX-Extractor equipment using a solvent (typically hexane) to dissolve the oil from the seed’s pallets/ cake, followed by separating solvent by FX-Miscella Distillation and FX-DeSolventiser toaster to recycle hexane by making process efficient with achieving best results of minimal hexane losses. The process involves:

- FX-Extractor - Uses solvent (typically hexane) to dissolve oil from seed pellets or cake.

- FX-Miscella Distillation - Separates the solvent from the extracted oil, ensuring clean recovery.

- FX-DeSolventiser Toaster - Removes residual solvent from the meal and recycles hexane for reuse.

Advanced Pre-N2 Miscella Refining

Ferro’s miscella refining is the proven new design concept in which partial refining is done at solvent extraction stage to 100% improve the oil quality than traditional refining steps.

- Integrated Design - Refining begins directly at the solvent extraction stage.

- Quality Improvement - Enhances oil quality up to 100% compared to traditional refining methods.

- Efficiency - Reduces processing steps while maintaining superior oil standards.

- Proven Concept - A reliable and innovative approach adopted to deliver consistent results.

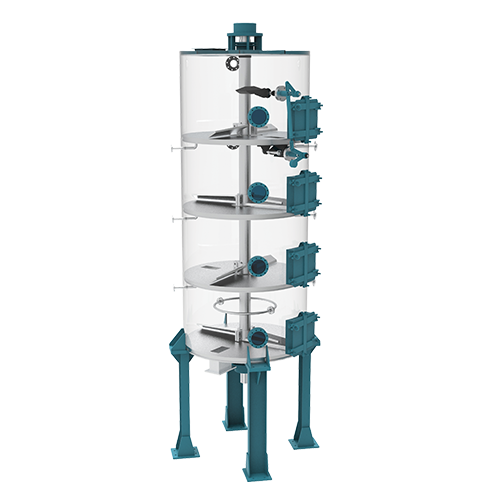

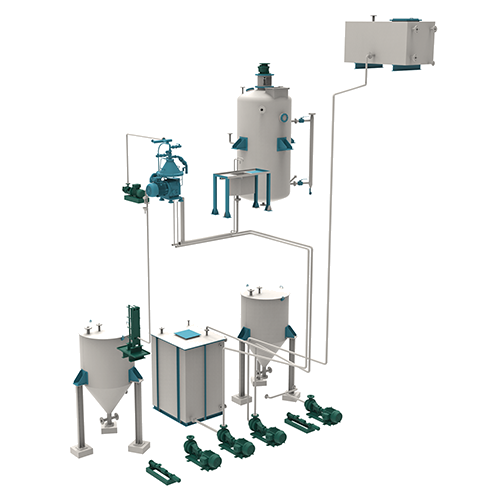

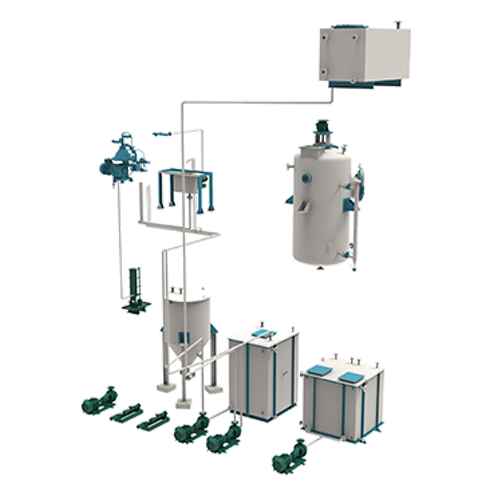

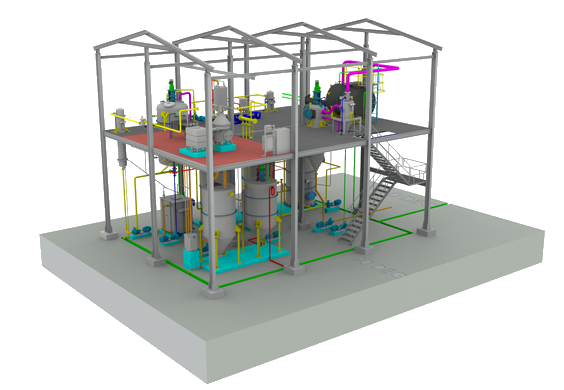

Cottonseed Refinery

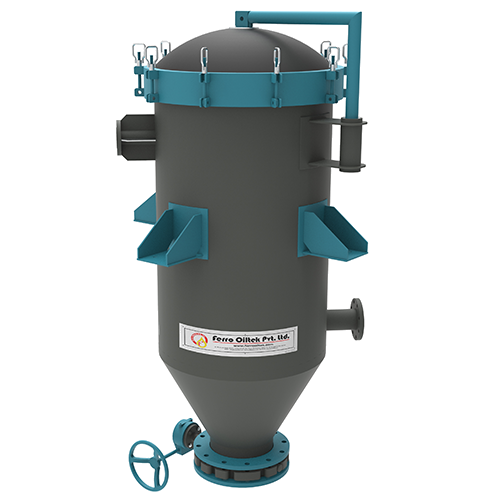

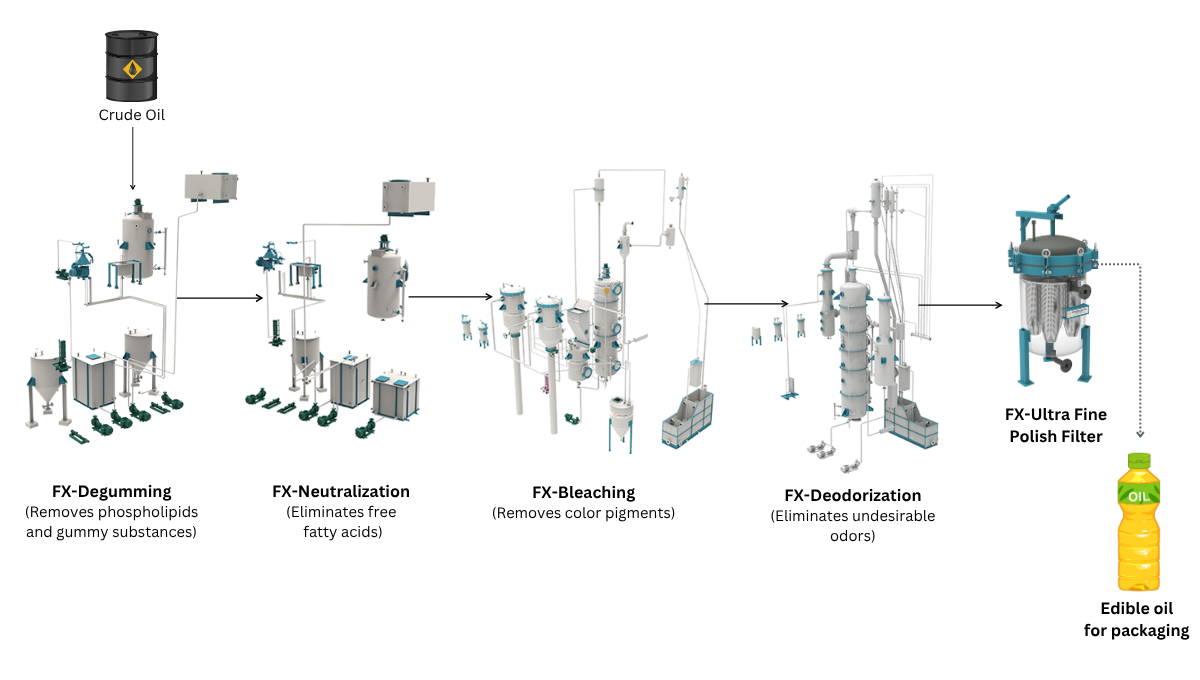

It is a traditional process that refines crude cottonseed oil to remove impurities like, FFA, colour pigment, phospholipids and odour to ensure it’s safe for consumption. It involves multiple stages, including FX-Degumming, FX-Neutralization, FX-Bleaching, and FX-Deodorization. Finally refined oil is further undergone through FERRO new design FX-Ultra Fine Polish filter to making ultra-pure polished oil for cooking.

- FX-Degumming - Removes phospholipids and gummy substances.

- FX-Neutralization - Eliminates free fatty acids to improve oil quality.

- FX-Bleaching - Removes color pigments and other impurities.

- FX-Deodorization - Eliminates undesirable odors and volatile compounds.

- FX-Ultra Fine Polish Filter - A FERRO new design filter that produces ultra-pure, polished cooking oil.

Get your edible oil plant with our solutions

Interested in this technology for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.