Edible Oil Solvent Extraction Technology

FERRO OILTEK offers advanced edible oilseed solvent extraction technology, engineered for optimal oil yield, minimal hexane losses, and maximum efficiency. Our reengineered extraction plant is designed to accommodate a wide range of extraction capacities, ensuring high-quality oil with minimal residuals.

In today’s oilseed processing environment, choosing the right extraction method is crucial. Mechanical pressing often leaves considerable residual oil; solvent extraction offers superior recovery — often reducing residuals to under 1%. With growing demand for quality edible oils, by-product meals and sustainable processing, solvent extraction stands out as the industrial standard for large-scale plants.

Ferro Oiltek’s Technology Features :

1. High Extraction Efficiency : Our modular FX-Extractor systems are designed to maximise oil recovery from a wide range of oilseeds (soy, sunflower, cottonseed, rice bran, mustard etc.).

2. Customisable Process Flow : Whether you are working with conventional seeds or specialty oils (high-oleic, omega-3 rich), our design adapts to your raw material and output targets.

3. Eco-Friendly Solvent Management: Our technology integrates advanced solvent recovery and minimal hexane loss systems, supporting both cost efficiency and environmental safety.

4. Robust Automation & Scalability: Automated controls and scalable modules ensure you can start with mid-capacity and expand as needed, with consistent performance and reliable operation.

5. By-Product Meal Recovery Integration: Our De-Solventizing & Toasting system ensures optimal extraction and meal quality, converting spent seed cake into protein-rich meals with minimal residual solvent.

Applications & Benefits

Our solvent extraction systems are suitable for plants processing a variety of oilseeds including soybeans, sunflower, cottonseed, rice bran and mustard seed. Thanks to high yield, you achieve more output per tonne of raw material, while quality by-products increase your overall margins. With advanced solvent recovery, operating expenditure (OPEX) is significantly reduced. For example, industry sources cite reduction of residual oil levels to below 0.5% and high yields exceeding 95%.

Why Choose Ferro Oiltek

- Proven experience in designing turnkey oilseed processing plants in India and abroad.

- End-to-end capability from preliminary seed pretreatment to solvent extraction and refinement.

- Strong after-sales support and spares network that ensures reliable performance and uptime.

- Commitment to sustainability, cost-efficiency and innovation — your partner in modern edible oil production.

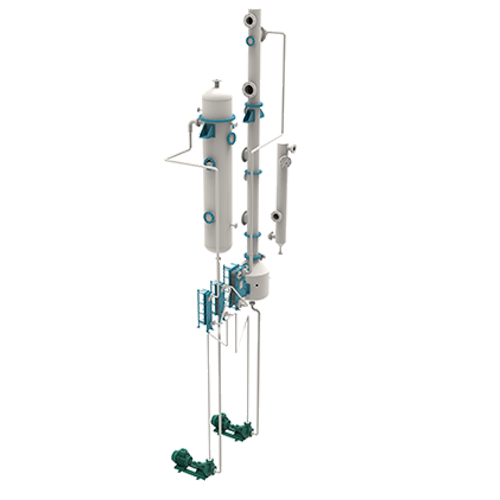

FERRO OILTEK's technology provides a sustainable, high-performance solution for edible oil production, setting new standards in efficiency and innovation. Our Solvent Extraction product range includes:

Processes :

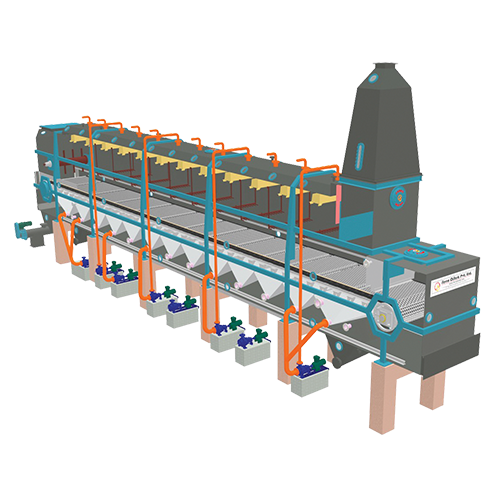

- FX-Extractor - primary stage solvent extraction module.

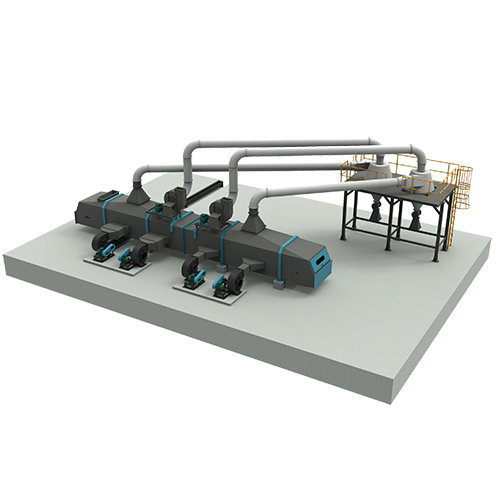

- FX-DeSolventizing & Toasting – ensures safe removal of solvent and produces toast meal ready for downstream use.

- FX-Horizontal Meal Dryer Cooler - efficient drying and cooling of meal to maintain nutritional integrity

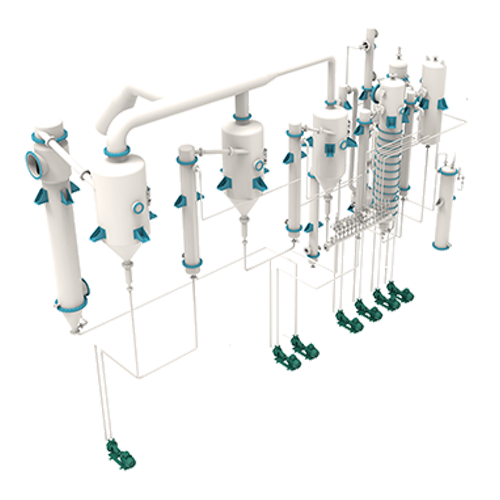

- FX-Miscella Distillation – separation of oil and solvent from miscella to produce crude oil and recover solvent.

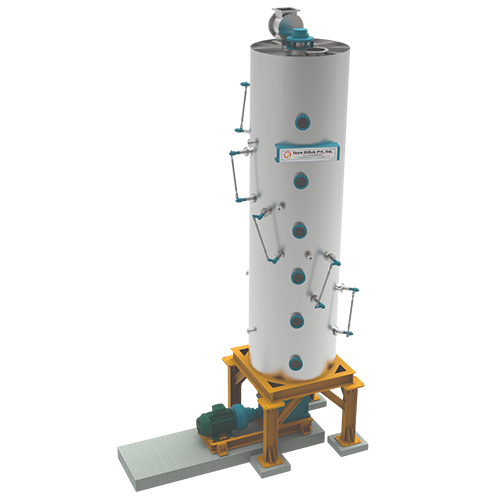

- FX-Recuperation Unit for final Solvent trap – last-stage solvent recovery to minimise solvent loss and reduce operating cost.