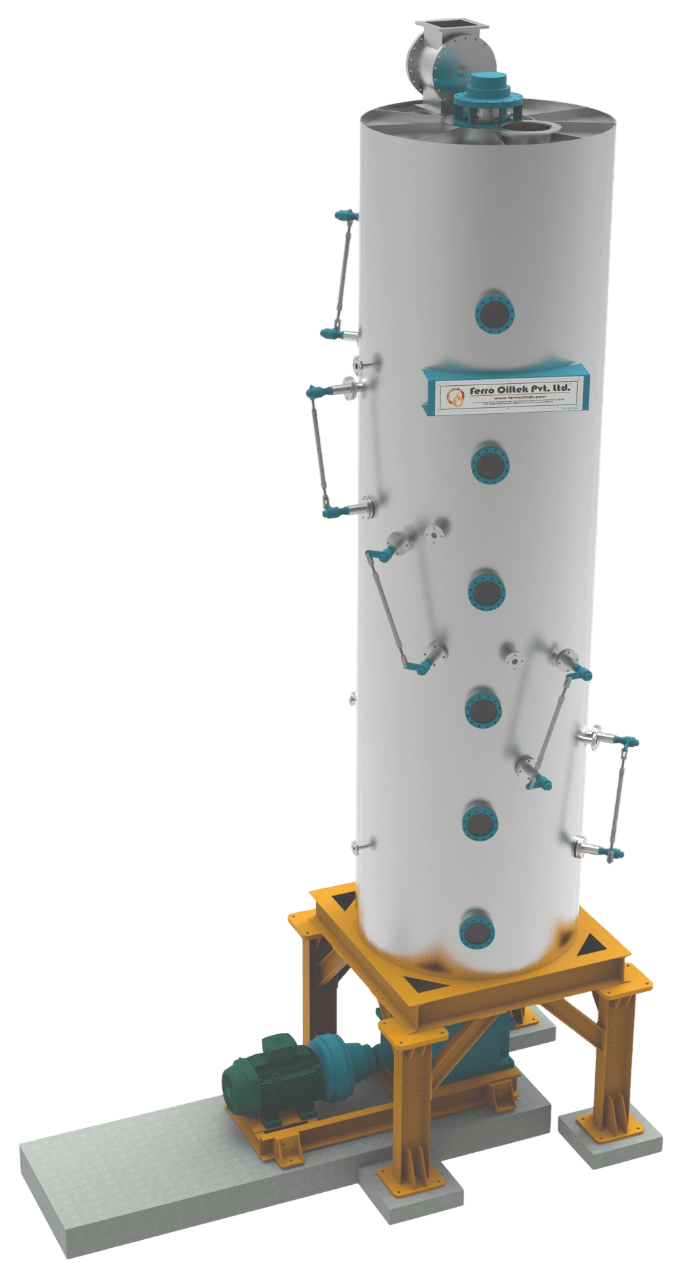

FX-DE-Solventizing & Toasting

Solvent Removal : The primary function of the desolventizing process is to remove the 30-35% solvent content from the meal, making it solvent-free and high in protein.

Enhanced Energy Efficiency : Provision of Automation on steam control & condensate handling reduces total energy consumption the overall desolventising operation become more efficient

Efficient Heating : Specially designed sparge trays provide direct heating, optimizing energy use

Easy Maintenance : Constructed with a single shell, the design allows for straightforward maintenance and quick service.

Optimized Steam Injection : The system includes a centrally driven shaft with a hardened scraper face and specially designed sparge trays for optimal steam addition, minimizing hexane losses.

Robust Construction: The design is built with durability in mind, ensuring long-lasting performance.

Factory-Aligned Drive Mechanism : The design is built with durability in mind, ensuring long-lasting performance.

Minimal Hexane Loss : The design significantly minimizes hexane loss, improving overall process efficiency.

Precision Engineering for Smooth Operation: Reengineered design concept and precise fabrication work done allow us very smooth running of all the rotating parts which results into low power consumption.

Toasting & Moisture Control : The system not only removes solvents but also toasts the meal, controlling anti-nutritional factors and reducing moisture and temperature to levels suitable for storage and transport.

Precise control of levels in each compartment.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.