FX-Deodorizer

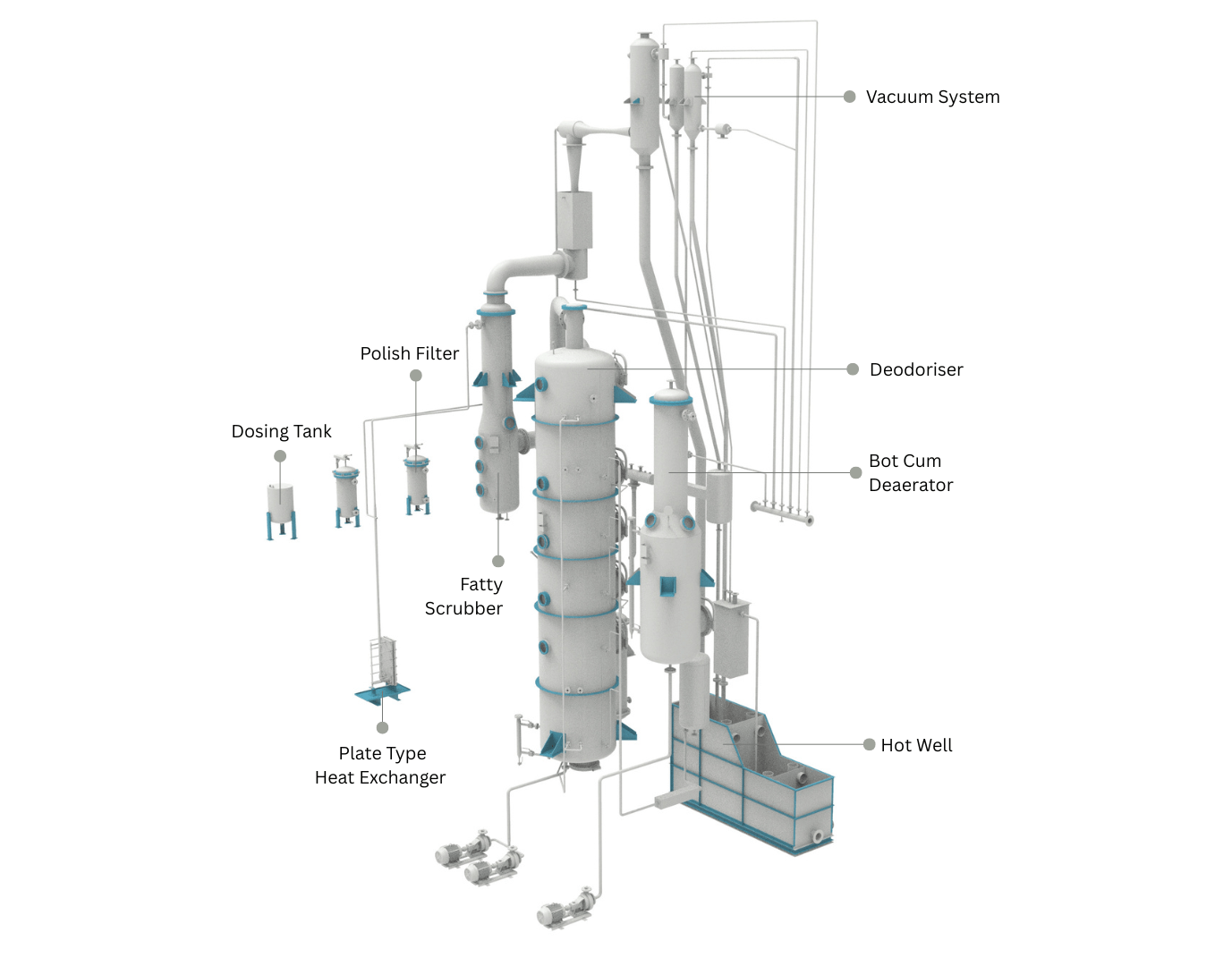

The final step in oil refining, deodorization uses steam distillation under vacuum to remove Free Fatty Acids (FFA), volatile compounds (like aldehydes and ketones), and contaminants based on their volatility and vapor pressure. In Ferro’s Deodorising section includes the main FX-Deodorizer vessel, FX-Fatty Acid Scrubber, FX-Deaerator vessel, Thermic fluid heater system, Vacuum system, Steam PRS, Plate type heat exchangers, FX-Polish filter etc. along with various sub-parts like flowmeters, pumps, control valves, etc.

- Stripping of Volatile Components : Effectively removes FFA, ensuring the peroxide value is minimized and secondary oxidation products.

- Oxidative Stability Enhancement: Improve shelf life by removing pro-oxidant compounds that accelerate oil degradation

- Off-Flavour Removal: Eliminates undesirable odors and flavors.

- Thermal Pigment Destruction: Prevents thermal damage and pigment degradation in the oil.

Advantages Of Ferro’s FX-Deodorizer

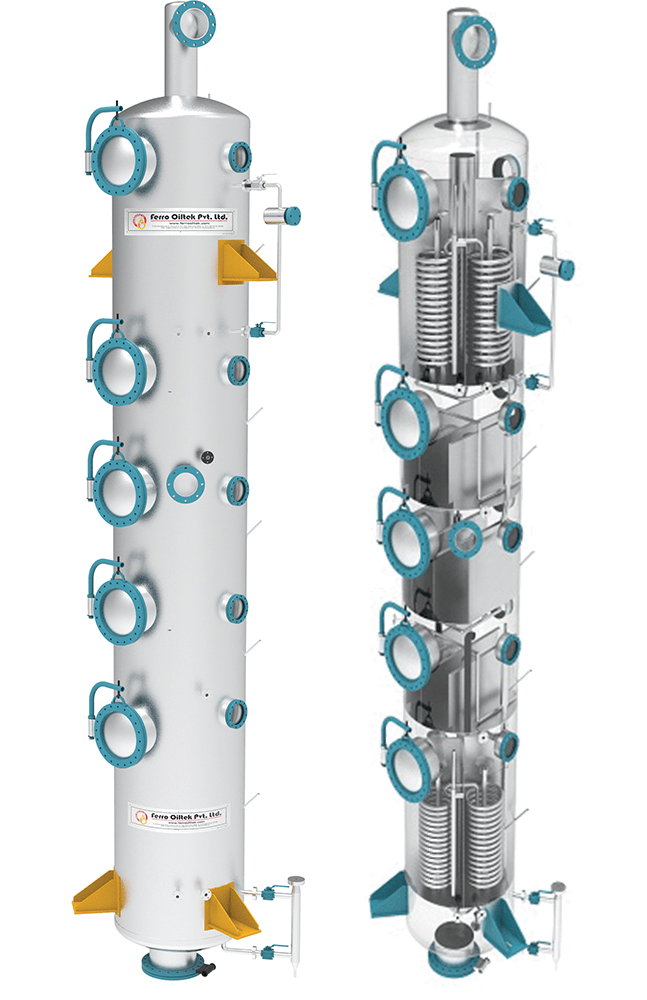

Made of SS-316 and SS-304 (customizable to customer requirements).

Features a multi-stage vertical pressure vessel with 5-6 compartments, optimizing the deodorization process.

Efficient Mechanisms within compartments enable the stripping of volatile components quickly.

The economical operational design concept optimizes functionality, reducing utility consumption and minimizing overall deodorization operating costs.

A well-designed vacuum system with these features ensures superior odour removal, enhanced oil stability, minimal nutrient loss, and energy-efficient operations, resulting in high-quality, odour-free edible oil.

Utilizing high-performance packing internals (pall rings or structured packings) with an enhanced surface area improves absorption efficiency at Fatty Acid Scrubbing operation.

Advanced Stripping & Retention Sections : Separate stripping and retention zones enable better control over thermal treatment, preventing oil degradation and reducing trans-fatty acid formation.

Selection & apply of high heat load and high heat exchange rate PHE results economic operation cost.

Comprehensive Safety Measures : Designed with thorough safety considerations for secure operation.

Flexible Capacity : Easily adjustable plant capacity within a defined range for optimal efficiency.

User-Friendly & Low Maintenance : Simple operation with minimal upkeep, ensuring long-term reliability.

Certified Equipment : All vessels and components are rigorously tested and certified for durability and performance.

We provide self-cleaning visible inspection window over equipment with branded high illuminated light.

Provide essential instrumentation package for utility control & equipment control to ensure optimal operating conditions and prevent damage.

Easy-access manhole & hand hole for inspection and maintenance

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.