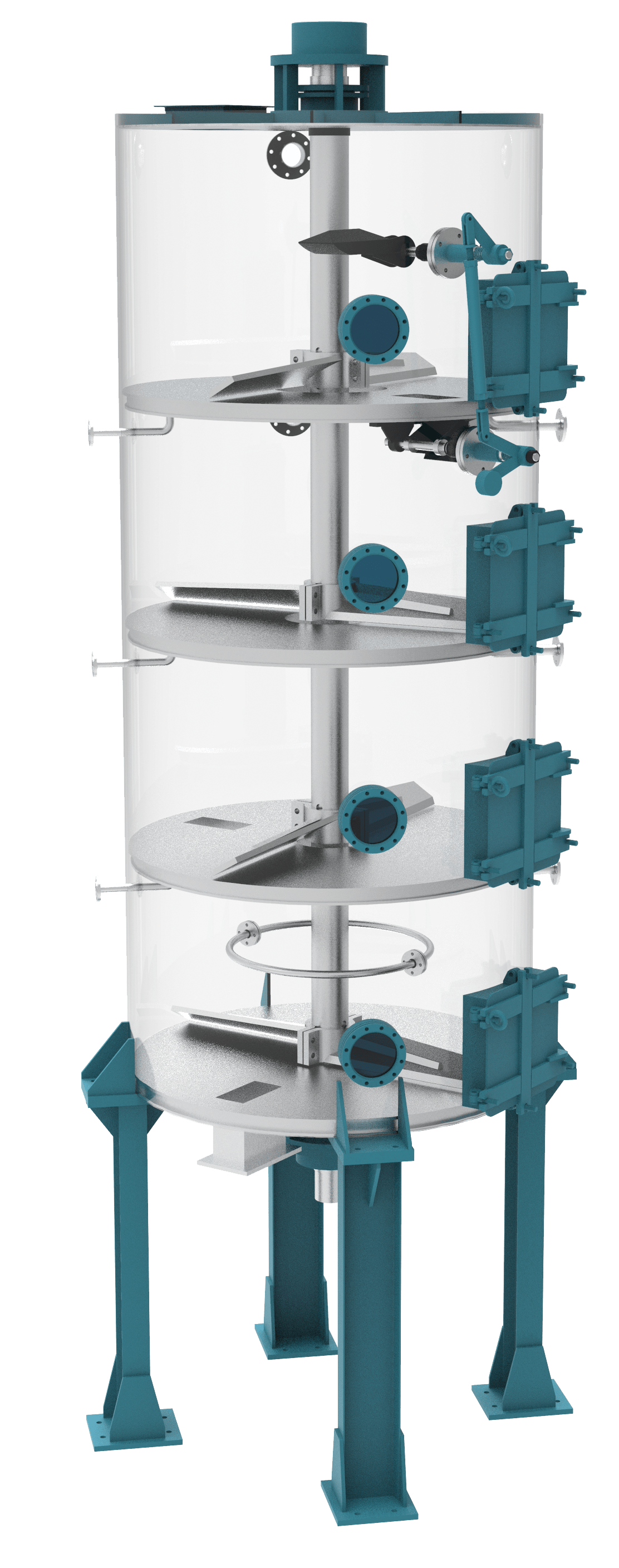

FX-Cooker Conditioning

The FX- Cooker is a high-performance machine designed for the pre-conditioning of oilseeds before flaking and expelling operation. It enhances oil recovery by optimizing moisture content, breaking down oil cell structures etc. which leading to efficient oil extraction. Cooking plays a crucial role in coagulating seed proteins while also sterilizing them by deactivating enzymes and inhibiting bacterial growth, ensuring optimal oil extraction and storage stability.

| Technical Specification | |||||

| Model | Stage | Diameter (Mm) | Heating Area (M²) | Power (Kw) | Approx Weight (Kg) Without Motor & Gb |

|---|---|---|---|---|---|

| FX-C18III | 3 | 1800 | 7.5 | 11.18 | 4000 |

| FX-C18V | 5 | 1800 | 12.5 | 15 | 6500 |

| FX-C22V | 5 | 2200 | 19 | 18.5 | 8500 |

| FX-C24VI | 6 | 2400 | 27 | 22 | 10500 |

| FX-C29VII | 7 | 2900 | 46 | 55 | 23500 |

| FX-C34IX | 9 | 3400 | 90 | 110 | 39500 |

| FX-C34X | 10 | 1800 | 12.5 | 15 | 44500 |

| FX-C40IX | 9 | 4000 | 113 | 160 | 63500 |

Note : The mentioned capacity depends on the input seed parameters.

Key Features

Provision of feed rate control ensures through VFD provide optimal accuracy, enhancing the overall efficiency of subsequent operations.

Apply FORBES make Precise thermal controlling system keeps maintaining not to damaging the oil cell during cooking.

The precise design concept of jacketed steam tray with using special MOC thoroughly hydrotested as per standards minimizes steam consumption, ensuring a cost-effective and energy-efficient operation.

Equipment undergone through Pressure test and penetrant-radiographic-ultrasound welding test ensuring guarantee on accuracy of operation and life of equipment.

Agitator Arms: Engineered for the best efficiency, the agitator arms feature precision-machined ends designed to prevent material buildup along the tray edges. Set at a specific angle to the cooker surface, they ensure complete material movement, minimizing residue on the base while protecting the integrity of the steam trays. Built with a robust two-part construction, these arms enhance durability and performance.

Providing Inspection windows for clear internal separation visibility.

Proper cooking and conditioning enhance flaking efficiency, optimizing performance in subsequent processes.

Fumes Catcher: The exhaust blower helps maintain the proper air flow, ensuring that excessive moisture or fumes are removed from the system. This keeps the operation safe and efficient, preventing pressure buildup and ensuring the plant maintains proper airflow.

Options of Bevel Helical & Planetary Gearbox: Ensuring higher productivity & low power consumption; long life.

The use of VFD ensures precise initial torque control for the compound drive system of basket beaters

Easy access door for inspection and maintenance.

Robust Construction : Built with carbon steel or stainless steel for durability and hygiene.

Safety guards with limit switches mitigate accident risks from rotating parts by triggering an instant shutdown if opened.

Customization Options

- Material Choice – Mild Steel / Stainless Steel (as per industry needs)

- Smart Control Mechanism – Fully automated seed/meat levels in each compartment, providing desired residence time

- Size Variants – Configurable for different plant capacities

- Automated Controls – PLC integration for precise process control like level and temperature

- Steam Optimization – Direct vs. indirect heating selection

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.