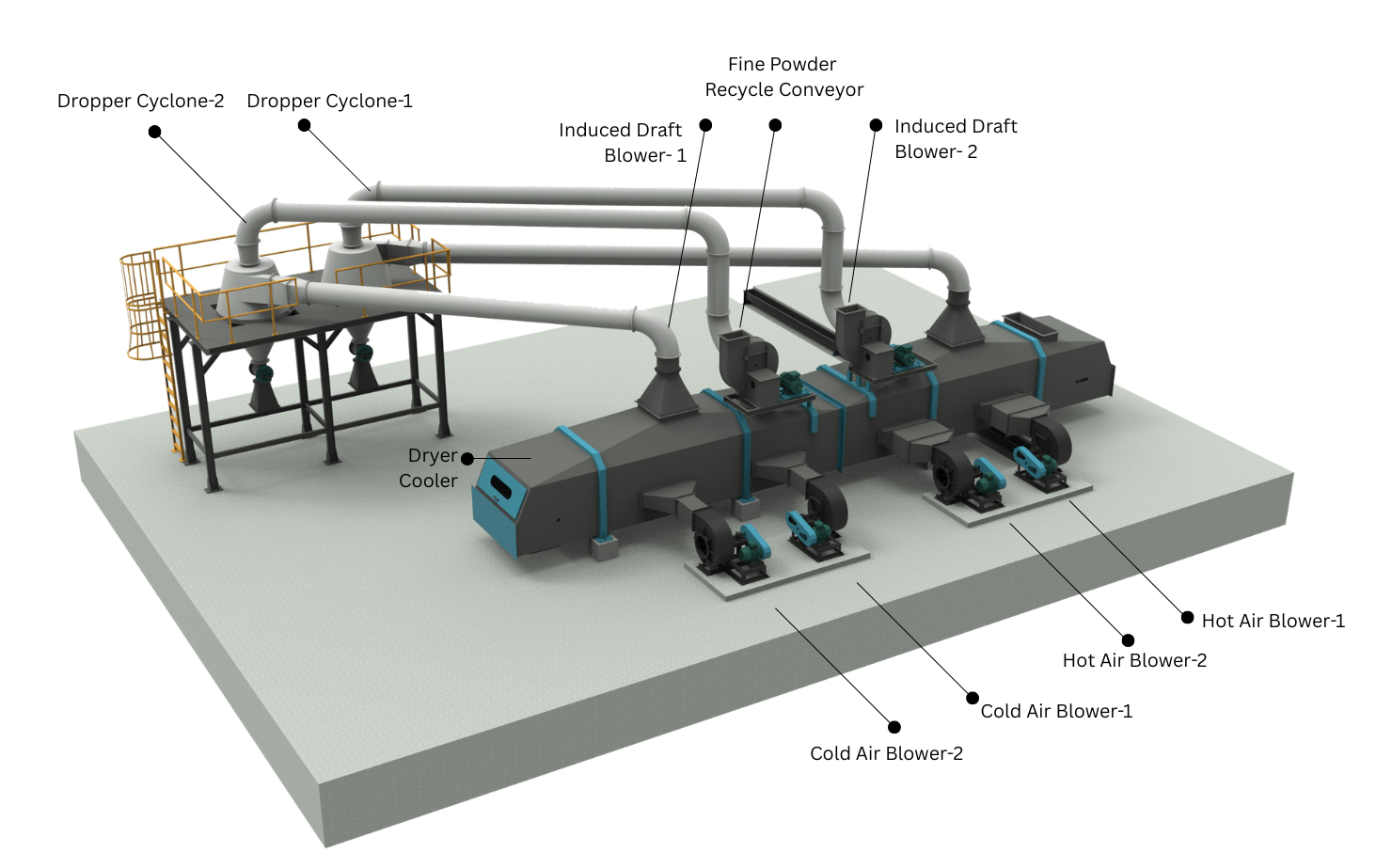

FX-Horizontal Dryer Cooler

The Horizontal Dryer/Cooler is designed for the efficient drying and cooling of SEP feed pellets, cakes and other meal. This system ensures uniform moisture reduction and temperature control, which results in outlet pellets, flakes and cakes stability & flow ability improves which helps in further enhancing the oil extraction efficiency.

Key Features

Provision of Specially designed perforated trays provide an optimal area for the flow of hot and cold air, helping maintain air pressure and velocity for efficient material processing, results in minimal requirement of power consumption.

The machine features a modular design that allows for easy expansion, providing flexibility to increase capacity as needed.

Minimal Downtime : The design ensures reduced downtime, promoting continuous operation and productivity.

Efficient Sealing : Each module is sealed to ensure zero mixing of air, optimizing the drying and cooling processes for maximum efficiency.

Low Maintenance Costs : The system is engineered with long-term maintenance in mind, significantly lowering ongoing maintenance expenses.

Self-Cleaning Design : Every tenth tray is equipped with a heat-resistant rubber scraper that effectively cleans fines that accumulate on the return side of the chain and bottom plate.

The dryer cooler uses a continuous chain with stainless steel (S.S) or galvanized mild steel (M.S) trays to carry the material, ensuring durability and smooth operation.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.