FX-PCAC: Air Cascade Pre-Cleaner

This machine is a combination of density separator and basket beater separator for better Read More

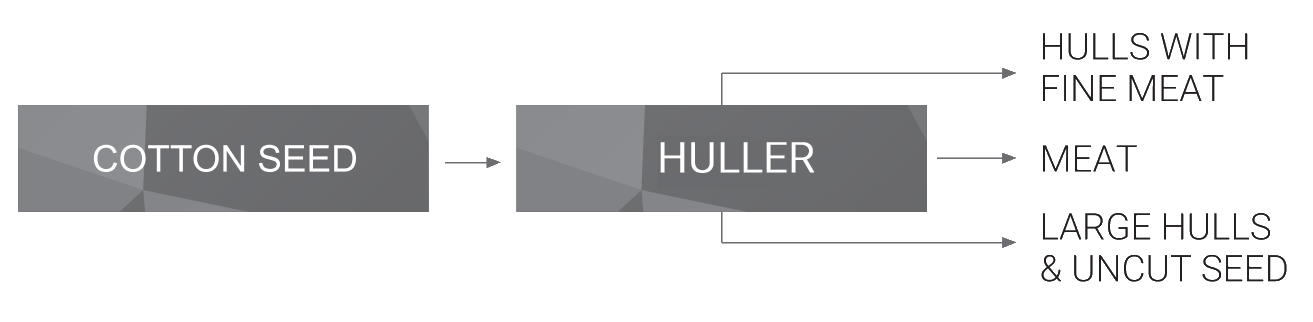

SEED PROCESSING

The FX Series Decorticator is used to dehull the oil seed (Cotton, Soya, Sunflower etc.) at very high efficiency & produces very minimum powder formation, which improves the production capacity & quality of product outlet.

The FX Series Decorticator equipment cuts the seed and separates the hulls & meat with very efficiently. The FX Series Decorticator has the provision of heavy duty twin roll magnetic feeder, which avoid the entry of metal particles into the DC machine. The Decorticator drums is made by special graded cold roll alloy steel with interchangeable knife, provision of heavy duty shaft & it is also mounted on heavy duty bearing & housing.

With the use of an adjustable feed damper and regulated speed control gives accurate & reliable feed rate which results in consistency in machine output.

In The FX Series Decorticator, the process of hulling begins with an adjustable mattered roll feeder attached with powerful magnets designed to offer an absolute consistency and uniformity to the flow rate and also control the foreign particles.

OPERATION OF TWIN ROLL HULLER:

Common motor drive for all basket beaters

We are providing special type of eccentric to get minimum power load consumption