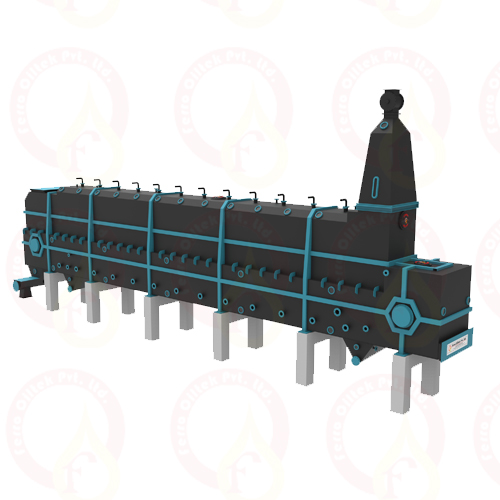

LM Extractor

In an LM Extractor, the material enters through an inlet hopper and is swiftly saturated with miscella.

Read More

Solvent Extraction

The purpose of the meal cooling section is for cooling the de-solventised and toasted material. The meal is passed through series of heating and cooling chamber so that the meal get uniform density as well as at the discharged meal should be cool enough to handle openly. The meal cooler is fitted with alloy steel straps, a special conveying chain, and perforated sheets. This helps fluidization of the meal, complete with the driving mechanism.