FX-Dewaxing / Winterization

The dewaxing process in edible oil refining involves the removal of waxes and other precipitable impurities that can cause cloudiness, especially at lower temperatures. This ensures the oil remains clear, stable, and visually appealing during storage and consumption.

FX- Dewaxing/Winterrization: A precise cooling during crystallization operation and filtration process removes waxes and other precipitable impurities from the oil, enhancing clarity, texture, and functional properties.

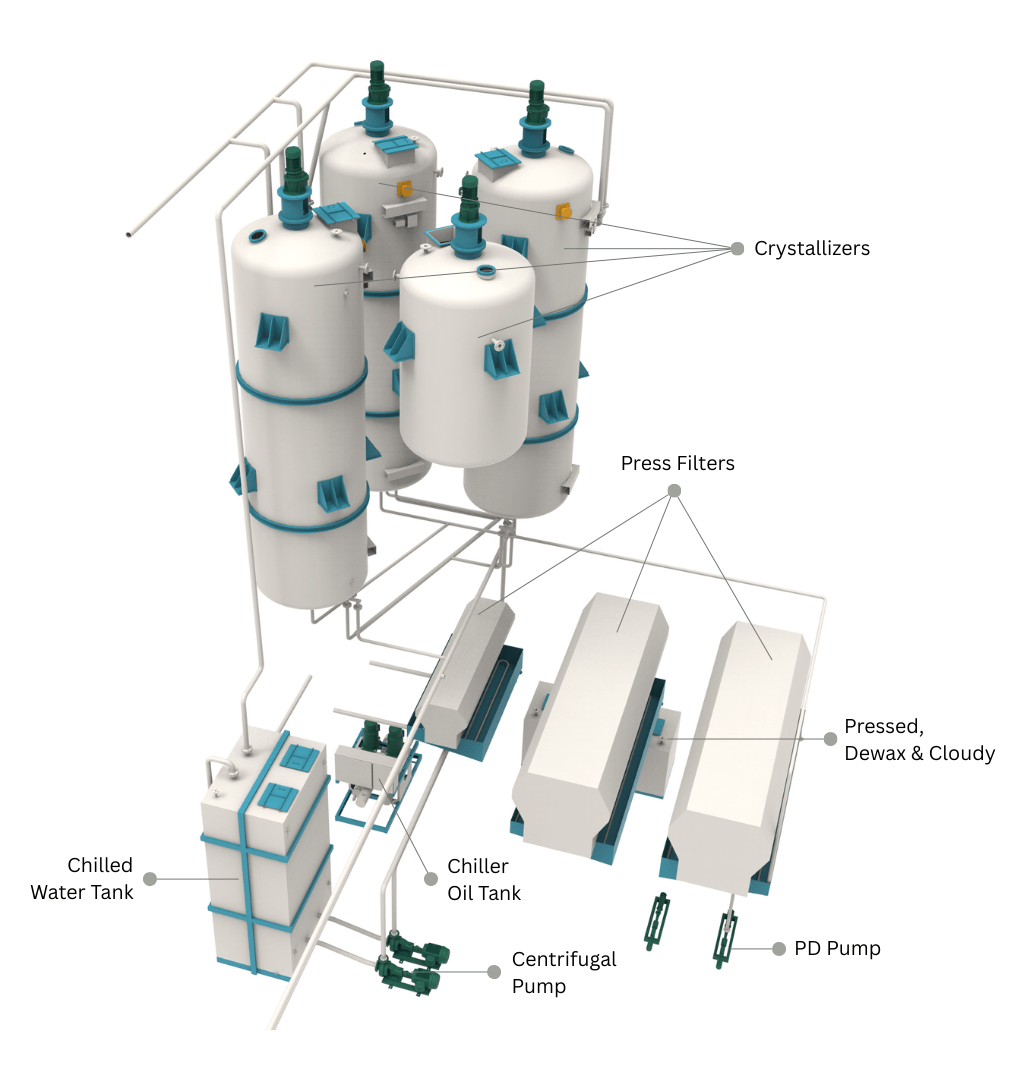

The dewaxing/ Winterization section includes FX- Crystallizer, Membrane Filter/ Filter Press, Chiller, Chilled water & Cold-water storage intermediate tank, Heat economising PHE, along with various sub-parts like flowmeters, pumps, control valves, etc.

- Removes waxes and other precipitable impurities from the oil.

- Preventing Oil Haziness

Advantages Of Ferro’s FX-Dewaxing / Winterization

The economical operational design concept optimizes functionality, reducing utility consumption and minimizing overall deodorization operating costs.

Provide essential instrumentation package for utility control & equipment control to ensure optimal operating conditions and prevent damage.

The self-cleaning design of coil tubes minimizes wax deposition, maintaining a constant heat transfer coefficient that enhances overall crystallization efficiency and reduces downtime.

Apply precise design crystallisation agitator efficiently mixing.

Flexible Capacity : Easily adjustable plant capacity within a defined range for optimal efficiency.

Certified Equipment : All vessels and components are rigorously tested and certified for durability and performance.

Comprehensive Safety Measures : Designed with thorough safety considerations for secure operation.

Precise temperature control to prevent oil degradation.

Energy-efficient cooling systems for cost-effective operations.

Automated filtration systems for consistent product quality.

Optimized retention time to ensure complete crystallization and maximum clarity.

User-Friendly & Low Maintenance : Simple operation with minimal upkeep, ensuring long-term reliability.

Easy-access manhole & hand hole for inspection and maintenance

Selection & apply of high heat load and high heat exchange rate PHE results economic operation cost.

We provide self-cleaning visible inspection window over equipment with branded high illuminated light.

The filtration system, featuring branded membrane filters or filter presses, is precisely engineered with optimal porosity to ensure exceptional dewaxing performance and crystal-clear oil quality.

Optimized Crystal Formation : Precisely controlled cooling rates ensure uniform crystallization, maximizing wax separation efficiency.

Quick Enquiry About This Product

Interested in this product for your project? Share your requirements, and our technical team will get back to you with detailed specifications, pricing, and availability. We're here to support your project's success with the right technology and expertise.